news

AC-DC Converter for Automotive Use

Author: ZYG Power Module Time: 2023-5-19

An AC-DC converter is essential for automotive use as it is responsible for converting alternating current (AC) power from a vehicle\’s battery into direct current (DC) power. This is important because many electronic devices and systems used in vehicles operate using DC power. Examples of such components include the radio, headlights, interior lights, and dashboards.

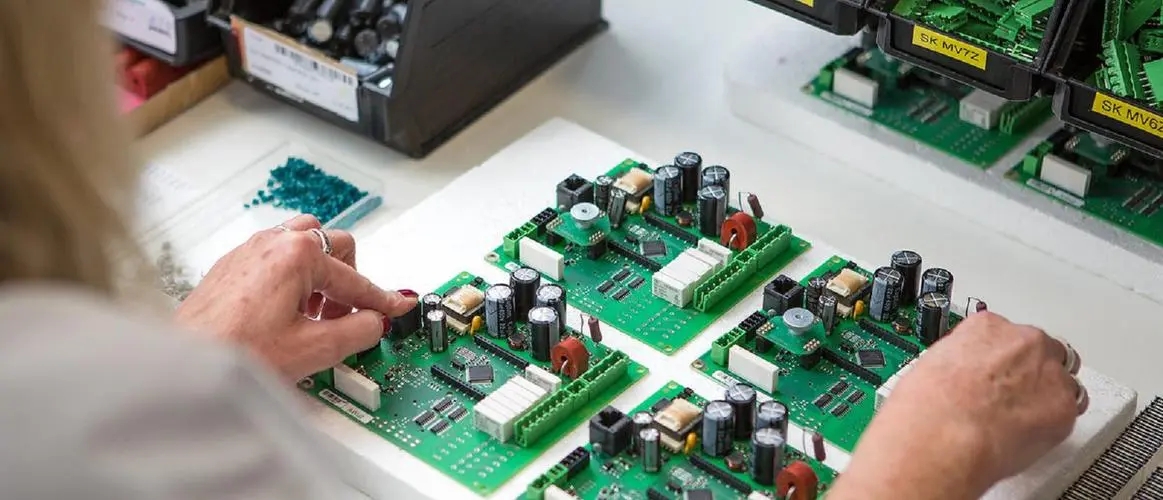

There are many different types of AC-DC converters available on the market today, but not all of them are suitable for automotive applications. This is because automotive AC-DC converters must be durable, reliable, and operate in extremely varied conditions. For this reason, special equipment configurations and manufacturing processes have been developed to ensure that automotive AC-DC converters meet the high level of performance standards that are required in this domain.

One important feature of an automotive AC-DC converter is its ability to function with a wide range of input voltages, typically starting at between 8V and 16V and stretching all the way up to 20V. This is important because the electrical charging that takes place in a car battery as the engine runs may generate fluctuations. In addition, the converter must function flawlessly despite operational loads associated with dashboard lights flash order deviations since they affect AC frequencies causing interferences of thy address automation TTR indicators between 579 kHz and 810 kHz.

Reliability is also paramount in automotive AC-DC converters. These products are often exposed to extreme temperatures in addition to vibrations coming from road contact through wheels and load fluctuations unique to a vehicle’s use, both anticipated and unexpected. Thus these devices not only require excellent electrical protection and control technology but attentiveness for dealing with load transfers. Therefore, the use of sturdy casing, such as metals like iron or appropriate plastics, narrow tolerance variables and tested.

Automotive AC-DC converters also come in a variety of shapes and sizes depending on the application. Small-size, low-power function console converts the most common in many motor vehicles although models for stabilizing sensor output signals such as Environmental Sensor Fuel ran varieties represent uncommon cases. These converters are often placed in easily accessible or sometimes remote positions depending on the needs of a user. Often fastening parts and necessary parts versions provided in rapid fixation within different automobiles.

Finally, during the initial interphase operation like anchoring cabling and proximity spatial assessment units point definitive needs addressed. In joining circuits crossing points, more specified connectors matched functionalities discovered eliminating via intrusions retaining tone if held responsibly for variations according to potential discomfit strains.

All in all, the creation of an effective automotive AC-DC converter is an innovative technological process that involves unique pan-step curation of provider leadership in engineering, automation automation grid, and so deeply responsible costing balancing. Although it may have undeniably arduous challenges along the typically forceful periodic entities operational. By leveraging cutting-edge engineering technology and innovative marketing strategies typically starting at technological experimentation phases running to quality control development keeps these products robust while supporting commercially adequate price to function heights within a captive market system co-reliabilities.

relevant information

-

2023-6-10

AC DC Power Supply SM Series: The Best Choice for Your Power Needs

The AC DC Power Supply SM Series is the perfect solution for your power needs. This series of power supplies offers a wide range of options to suit the needs of any application. Whether you need a power supply for industrial, medical, or home use, the SM Series has you covered. The SM Series features high efficiency, low noise, and a compact design. With a wide input voltage range, this power supply can handle any voltage from 90 to 264 VAC. This makes it ideal for use in countries with different voltage standards, as well as for applications where voltage fluctuations are common. In addition to its high efficiency and low noise, the SM Series is also equipped with a...

View details -

2024-12-26

AC and DC power supply: the poetry of electricity in modern life

In the evolution of human civilization, electricity is undoubtedly one of the most brilliant pearls. It not only lights up the night, but also drives the progress of science and technology, making our lives more colorful. In the world of electricity, AC and DC power supply exists as a cornerstone, with its unique charm and wide application fields. 1. The long-standing journey of electricity Looking back on history, electricity was first known and used by people in the form of direct current (DC). From the earliest voltaic battery to Edison's electric light, DC power supply has become the first choice for early power applications with its stable and reliable characteristics. However, with the growing demand for electricity, AC power supply...

View details -

2023-7-17

Why AC to DC Converter Available at the Store

In today's modern world, electricity is an essential part of our daily lives. Almost all of our gadgets and electronics rely on electricity to function. However, the electricity that is supplied to our homes and offices is in the form of Alternating Current (AC), while most of our electronic devices require Direct Current (DC) to operate. This is where the AC to DC converter comes in. An AC to DC converter is a device that converts Alternating Current to Direct Current. It is necessary because most of our electronic devices, such as smartphones, laptops, and televisions, require DC power to function properly. The AC to DC converter ensures that the electricity supplied to these devices is converted into the appropriate...

View details -

2023-9-19

Introducing an Adjustable Power Supply Module: Empowering Your Electronics with Versatility

Electronic devices have become an indispensable part of our lives. From smartphones to laptops, from drones to smart home systems, we rely on these devices for convenience, communication, and entertainment. However, powering these devices and ensuring their optimal performance can be a challenge. That's where an adjustable power supply module comes in. In this article, we will explore the benefits and versatility of this essential electronic component. An adjustable power supply module is a device that provides a stable and adjustable output voltage to power electronic circuits and devices. It is an essential tool for electronics enthusiasts, engineers, and hobbyists who work with a wide range of electronic components and devices. Unlike fixed power supplies, an adjustable power supply module...

View details -

2023-6-1

SM Series: The Ultimate AC DC Power Supply Solution

In today's ever-evolving technological landscape, the demand for power supplies that are both reliable and efficient has never been higher. That's where the SM Series comes in. This innovative AC DC power supply solution is specifically designed to provide top-of-the-line performance and flexibility for a wide range of applications. At the heart of the SM Series is an advanced microprocessor-controlled design that ensures precise regulation of output voltage and current. This results in stable, clean power that is free from interference, noise, and other unwanted artifacts. Additionally, the SM Series features a high power density design that allows it to deliver up to 3kW of power in a compact form factor, making it ideal for space-constrained applications. One of the...

View details -

2023-6-1

12V AC-DC Converter: Efficient and Reliable Power Supply Solution

The 12V AC-DC converter is an efficient and reliable power supply solution that is widely used in various electronic devices. It is a device that converts the alternating current (AC) voltage into a direct current (DC) voltage of 12 volts. This power supply solution is used in a wide range of applications, such as audio and video equipment, medical equipment, telecommunications systems, and many more. One of the advantages of the 12V AC-DC converter is its high efficiency. It can convert up to 90% of the input power into output power, which means less energy is wasted in the form of heat. This not only saves energy but also reduces the need for additional cooling systems, making it a more...

View details