الإخبارية

The Importance of Quality Control in China DC-DC Converter Manufacturing

المؤلف : ZYG Power Module Time: 2023-3-31

Quality control is crucial in every aspect of manufacturing, especially in China DC-DC converter manufacturing. DC-DC converters are devices that convert one voltage level to another and are used in various industries, including automotive, aerospace, medical, and electronics. Quality control ensures that the DC-DC converters meet the required specifications, performance standards, and safety regulations. In this article, we will discuss the importance of quality control in China DC-DC converter manufacturing.

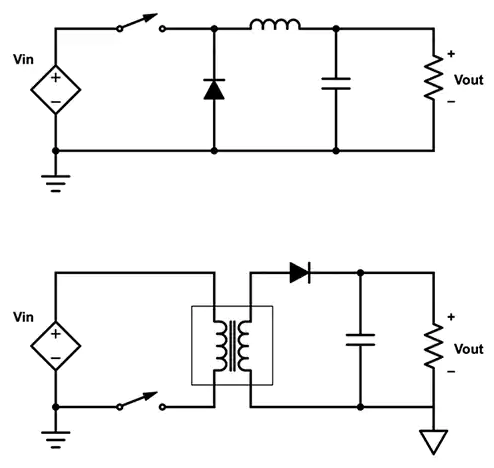

DC-DC Converter Basics

DC-DC converters are devices that convert one voltage level to another. They are made up of several components, including inductors, capacitors, diodes, and transformers. The converter operates by using pulse width modulation to regulate the output voltage as per the input signal. These converters come in various sizes, shapes, and models to meet the different needs of various industries.

Meeting Performance Standards

Quality control plays a vital role in ensuring that DC-DC converters meet the required performance standards. The performance standards include efficiency, output voltage, and ripple current. Manufacturers must adhere to these standards to ensure that the devices perform optimally under various operating conditions. Quality control checks ensure that the devices meet the targeted specifications and standardization requirements of the intended application.

Enhanced Safety

Quality control is critical in enhancing the safety of DC-DC converters. The converters operate at high voltage levels, making it essential to ensure that the devices are safe for use. Quality control ensures that the devices comply with safety regulations, such as electromagnetic compatibility (EMC) standards and thermal management to prevent overheating. Additionally, quality control checks ensure that there are no defects in the converter that could result in a hazard for the end-users.

Minimizing Defects

Quality control helps to minimize the instances of defects in DC-DC converters by identifying any anomalies in the early stages of production. Manufacturers can use various quality control techniques such as Statistical Process Control (SPC) and Failure Mode and Effects Analysis (FMEA) to detect and resolve issues before production starts. By minimizing the number of defects, manufacturers can reduce production costs and improve customer satisfaction.

Product Reliability

DC-DC converters must be reliable to meet the needs of various industries such as defense, aerospace, and medical. Quality control ensures that the devices are reliable by testing them under various conditions to ensure that they can perform optimally under varying environments. Additionally, quality control checks ensure that the devices are durable and can withstand physical and thermal stresses.

Customer Satisfaction

The quality of DC-DC converters is essential in ensuring customer satisfaction. Customers expect products to meet their specific requirements and operate as expected. Quality control checks ensure that the devices meet these requirements, and they are tested to ensure that they perform optimally. By achieving customer satisfaction, manufacturers can build a reputation for providing high-quality products leading to repeat orders and positive word of mouth.

Efficiency and Cost-Effectiveness

Quality control plays a role in improving the efficiency and cost-effectiveness of DC-DC converter manufacturing. By ensuring that the devices meet the required specifications and standards, manufacturers can reduce the number of errors, rework, wastage, and associated costs. Additionally, quality control checks ensure that the production processes are optimized and streamlined for maximum efficiency.

خاتمة

Quality control is crucial in China DC-DC converter manufacturing as it ensures that the devices meet the required specifications, performance standards, and safety regulations. Quality control helps to enhance product reliability, customer satisfaction, and cost-effectiveness of manufacturing. Manufacturers must invest in quality control techniques such as SPC and FMEA to minimize defects and optimize the production process. By doing so, they can ensure that the devices perform optimally under varying conditions and environments. With the increasing demand for DC-DC converters across various industries, manufacturers must strive to provide high-quality products through quality control, ultimately leading to business growth and customer satisfaction.

سابق: كيفية حل مشكلة اختيار وحدة الطاقة

التالي: مستقبل مصانع محول التيار المتردد والتيار المتردد: اتجاهات وتقنيات تستحق المشاهدة

معلومات ذات صلة

-

2023-6-8

The DP Series DC-DC Converter is a highly efficient and reliable device that is widely used in various industrial and commercial applications. This converter is designed to convert a DC voltage from one level to another, providing a stable output voltage that is suitable for powering various electronic devices. One of the most important features of the DP Series DC-DC Converter is its high efficiency. This converter has a conversion efficiency of up to 95%, which means that it wastes very little energy during the conversion process. This high efficiency makes it an ideal choice for applications where power consumption is a critical factor. Another important feature of the DP Series DC-DC Converter is its wide input voltage range. This...

عرض التفاصيل -

2023-11-4

DC to DC Power Supply Module: Efficient and Reliable Solution for Voltage Conversion

Introduction: DC to DC power supply modules are electronic devices that convert one DC voltage level into another. They play a crucial role in various electronic systems, where different voltage levels are required for proper functioning. These modules are highly efficient and reliable, making them an essential component in industries like telecommunications, automotive, aerospace, and renewable energy. Efficiency of DC to DC Power Supply Module: One of the key advantages of using a DC to DC power supply module is its high efficiency. These modules are designed to operate with minimal power loss during the conversion process. Unlike traditional linear regulators, DC to DC power supply modules utilize switching techniques, such as pulse width modulation (PWM) or frequency modulation (FM),...

عرض التفاصيل -

2023-6-5

DC DC Converter EX Series: A Powerful and Reliable Solution for Your Power Management Needs

In today\'s fast-paced and technology-driven world, the need for efficient power management solutions has become more important than ever. Whether you are working with industrial machinery, electronic devices, or power-sensitive applications, you need a reliable and high-performance DC DC converter to ensure stable and efficient power supply. This is where the DC DC Converter EX Series comes in – a powerful and versatile solution designed to meet the diverse needs of modern power management. What is the DC DC Converter EX Series? The DC DC Converter EX Series is a range of high-performance DC DC converters designed to deliver reliable and efficient power management for a wide range of applications. These converters are built using advanced technology, innovative design, and...

عرض التفاصيل -

2023-6-15

Revolutionizing Power Management with Bi-Directional Converters

In recent years, the demand for more efficient and reliable power management systems has grown significantly. One solution to this problem is the use of bi-directional converters. These converters have the ability to transfer power in both directions between two different DC power sources, making them ideal for a wide range of applications. Bi-directional converters are particularly useful in renewable energy systems, where the energy generated from sources like solar or wind power can be stored and used when needed. By using bi-directional converters, excess energy can be stored in batteries or fed back into the grid, providing a more efficient and sustainable energy solution. One major advantage of bi-directional converters is their ability to minimize power loss. Traditionally, power...

عرض التفاصيل -

2023-10-14

High Voltage Power Supply Module: Safely Empowering Electrical Systems

In today\'s world, with the ever-increasing demand for electricity, high voltage power supply modules play a crucial role in safely empowering electrical systems. These modules are designed to provide a stable and reliable source of high voltage power, ensuring the smooth operation of various devices and systems. In this article, we will explore the importance of high voltage power supply modules and how they contribute to the overall safety and efficiency of electrical systems. One of the primary functions of a high voltage power supply module is to convert low voltage input into high voltage output. This conversion process involves various stages, including rectification, filtering, and voltage regulation. By effectively managing these stages, the module ensures that the output voltage...

عرض التفاصيل -

2023-6-28

AC DC Power Supply SD Series: Reliable and Efficient

The SD Series of AC DC power supply is a versatile and reliable power solution that is designed for a wide range of applications. With a power output capacity ranging from 5W to 300W, the SD Series is suitable for use in various electronic devices, such as industrial automation systems, LED lighting, medical devices, and consumer electronics. One of the key features of the SD Series is its high efficiency. With an efficiency rating of up to 91%, the power supply is able to convert AC input power into DC output power with minimal losses, resulting in lower heat generation and energy consumption. This not only helps to reduce operating costs, but also extends the lifespan of the power supply...

عرض التفاصيل