nyheder

Vigtigheden af kvalitetskontrol i Kina DC-DC Converter Manufacturing

Author: ZYG Power Module Time: 2023-3-31

Quality control is crucial in every aspect of manufacturing, especially in China DC-DC converter manufacturing. DC-DC converters are devices that convert one voltage level to another and are used in various industries, including automotive, aerospace, medical, and electronics. Quality control ensures that the DC-DC converters meet the required specifications, performance standards, and safety regulations. In this article, we will discuss the importance of quality control in China DC-DC converter manufacturing.

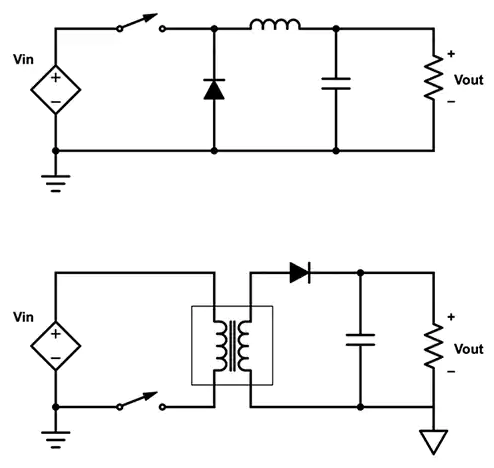

DC-DC Converter Basics

DC-DC converters are devices that convert one voltage level to another. They are made up of several components, including inductors, capacitors, diodes, and transformers. The converter operates by using pulse width modulation to regulate the output voltage as per the input signal. These converters come in various sizes, shapes, and models to meet the different needs of various industries.

Meeting Performance Standards

Quality control plays a vital role in ensuring that DC-DC converters meet the required performance standards. The performance standards include efficiency, output voltage, and ripple current. Manufacturers must adhere to these standards to ensure that the devices perform optimally under various operating conditions. Quality control checks ensure that the devices meet the targeted specifications and standardization requirements of the intended application.

Enhanced Safety

Quality control is critical in enhancing the safety of DC-DC converters. The converters operate at high voltage levels, making it essential to ensure that the devices are safe for use. Quality control ensures that the devices comply with safety regulations, such as electromagnetic compatibility (EMC) standards and thermal management to prevent overheating. Additionally, quality control checks ensure that there are no defects in the converter that could result in a hazard for the end-users.

Minimizing Defects

Quality control helps to minimize the instances of defects in DC-DC converters by identifying any anomalies in the early stages of production. Manufacturers can use various quality control techniques such as Statistical Process Control (SPC) and Failure Mode and Effects Analysis (FMEA) to detect and resolve issues before production starts. By minimizing the number of defects, manufacturers can reduce production costs and improve customer satisfaction.

Product Reliability

DC-DC converters must be reliable to meet the needs of various industries such as defense, aerospace, and medical. Quality control ensures that the devices are reliable by testing them under various conditions to ensure that they can perform optimally under varying environments. Additionally, quality control checks ensure that the devices are durable and can withstand physical and thermal stresses.

Customer Satisfaction

The quality of DC-DC converters is essential in ensuring customer satisfaction. Customers expect products to meet their specific requirements and operate as expected. Quality control checks ensure that the devices meet these requirements, and they are tested to ensure that they perform optimally. By achieving customer satisfaction, manufacturers can build a reputation for providing high-quality products leading to repeat orders and positive word of mouth.

Efficiency and Cost-Effectiveness

Quality control plays a role in improving the efficiency and cost-effectiveness of DC-DC converter manufacturing. By ensuring that the devices meet the required specifications and standards, manufacturers can reduce the number of errors, rework, wastage, and associated costs. Additionally, quality control checks ensure that the production processes are optimized and streamlined for maximum efficiency.

Conclusion

Quality control is crucial in China DC-DC converter manufacturing as it ensures that the devices meet the required specifications, performance standards, and safety regulations. Quality control helps to enhance product reliability, customer satisfaction, and cost-effectiveness of manufacturing. Manufacturers must invest in quality control techniques such as SPC and FMEA to minimize defects and optimize the production process. By doing so, they can ensure that the devices perform optimally under varying conditions and environments. With the increasing demand for DC-DC converters across various industries, manufacturers must strive to provide high-quality products through quality control, ultimately leading to business growth and customer satisfaction.

Tidligere: How to solve the problem of power module selection

Næste: Fremtiden for AC-DC-konverterfabrikker: Trends og teknologier at se

relevant information

-

2023-7-6

120V AC to 12V DC Converter: Efficient Power Conversion for Electronics

Introduction: In the world of electronics, power conversion plays a crucial role in ensuring the smooth functioning of various devices. One such essential conversion is from 120V alternating current (AC) to 12V direct current (DC). This article aims to explore the significance of a 120V AC to 12V DC converter, its working principle, and its application in efficiently powering a wide range of electronic devices. Understanding the Need for a 120V AC to 12V DC Converter: Most electronic appliances and devices, such as smartphones, laptops, LED lights, and car audio systems, operate on low voltage DC power. However, the power supplied to our homes and businesses is typically high voltage AC power. Hence, a conversion is necessary to ensure compatibility...

Se detaljer -

2023-7-11

AC DC Converter SPM Series: Efficient Power Conversion Solutions for Your Electrical Needs

In today's fast-paced and technology-driven world, efficient power conversion solutions are essential to meet the increasing demands of various electrical applications. And when it comes to reliable and high-performance AC DC converters, the SPM series stands out as a top choice. Designed to provide efficient power conversion solutions, the SPM series offers a wide range of benefits and features that make it the ideal choice for a diverse range of electrical needs. The SPM series is known for its exceptional efficiency, which is crucial in reducing energy consumption and minimizing heat dissipation. With an efficiency rating of up to 98%, these converters ensure that the power is converted with maximum efficiency, resulting in reduced energy costs and increased overall system...

Se detaljer -

2023-8-4

China AC-DC Power Supply manufacture: Efficiently Converting Alternating Current to Direct Current

Introduction In today's world, electricity is an indispensable part of our lives. From powering our homes to fueling industries, electricity plays a crucial role in powering various devices and machinery. One of the key components that facilitate this conversion of electrical energy is the AC-DC power supply. In this article, we will explore the importance of AC-DC power supplies, how they efficiently convert alternating current to direct current, and their various applications. Understanding Alternating Current and Direct Current Before delving into the intricacies of AC-DC power supplies, it is essential to understand the basics of alternating current (AC) and direct current (DC). Alternating current is the type of electricity that flows in both directions, oscillating periodically. It is the standard...

Se detaljer -

2024-9-23

New energy high-voltage power supply: the core driving force of green transformation

With the growing global awareness of sustainable development and environmental protection, the new energy industry is booming at an unprecedented pace as a key force for promoting the green transformation of the future economy and society. In this wave, high-voltage power supply technology, as one of the core components of the new energy system, is becoming increasingly important. In this article, the definition, technical characteristics, application areas and future development trends of new energy high-voltage power supply are discussed in detail. 1. Definition of New Energy High Voltage Power Supply In short, new energy high voltage power supply refers to power supply equipment designed for the new energy field, which can output high voltage and high current. This type of...

Se detaljer -

2023-9-18

AC/DC 5V Power Supply Module: Stable and Efficient Voltage Conversion Solution

We rely on smartphones, laptops, tablets, and various other gadgets to stay connected, informed, and entertained. However, all these devices require a stable and efficient power supply to function optimally. This is where the AC/DC 5V Power Supply Module comes into play. The AC/DC 5V Power Supply Module is a cutting-edge technology that provides a stable and efficient voltage conversion solution for various electronic devices. It converts alternating current (AC) power from the main power supply to direct current (DC) power with a voltage output of 5 volts. This ensures that electronic devices receive a constant and reliable power supply, preventing any fluctuations or interruptions that could potentially damage the device. One of the key features of the AC/DC 5V...

Se detaljer -

2023-10-16

Unleash the Power: Discover the Best Fully Modular Power Supply

In the world of technology, power is everything. Whether you are a gamer, a content creator, or simply a tech enthusiast, having a reliable and efficient power supply is crucial for your system's performance and overall experience. One power supply that stands out from the rest is the fully modular power supply. With its advanced features and flexibility, it is truly a game-changer. A fully modular power supply is designed to provide maximum customization and convenience. Unlike traditional power supplies, where all the cables are permanently attached, the fully modular power supply allows you to connect only the cables you need. This means you can eliminate unnecessary clutter and optimize airflow within your system, resulting in better cooling and improved...

Se detaljer