news

L'importanza del controllo di qualità nella produzione di convertitori CC-CC in Cina

Author: ZYG Power Module Time: 2023-3-31

Quality control is crucial in every aspect of manufacturing, especially in China DC-DC converter manufacturing. DC-DC converters are devices that convert one voltage level to another and are used in various industries, including automotive, aerospace, medical, and electronics. Quality control ensures that the DC-DC converters meet the required specifications, performance standards, and safety regulations. In this article, we will discuss the importance of quality control in China DC-DC converter manufacturing.

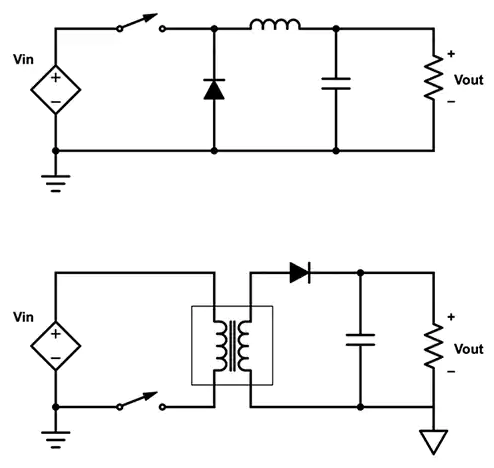

DC-DC Converter Basics

DC-DC converters are devices that convert one voltage level to another. They are made up of several components, including inductors, capacitors, diodes, and transformers. The converter operates by using pulse width modulation to regulate the output voltage as per the input signal. These converters come in various sizes, shapes, and models to meet the different needs of various industries.

Meeting Performance Standards

Quality control plays a vital role in ensuring that DC-DC converters meet the required performance standards. The performance standards include efficiency, output voltage, and ripple current. Manufacturers must adhere to these standards to ensure that the devices perform optimally under various operating conditions. Quality control checks ensure that the devices meet the targeted specifications and standardization requirements of the intended application.

Enhanced Safety

Quality control is critical in enhancing the safety of DC-DC converters. The converters operate at high voltage levels, making it essential to ensure that the devices are safe for use. Quality control ensures that the devices comply with safety regulations, such as electromagnetic compatibility (EMC) standards and thermal management to prevent overheating. Additionally, quality control checks ensure that there are no defects in the converter that could result in a hazard for the end-users.

Minimizing Defects

Quality control helps to minimize the instances of defects in DC-DC converters by identifying any anomalies in the early stages of production. Manufacturers can use various quality control techniques such as Statistical Process Control (SPC) and Failure Mode and Effects Analysis (FMEA) to detect and resolve issues before production starts. By minimizing the number of defects, manufacturers can reduce production costs and improve customer satisfaction.

Product Reliability

DC-DC converters must be reliable to meet the needs of various industries such as defense, aerospace, and medical. Quality control ensures that the devices are reliable by testing them under various conditions to ensure that they can perform optimally under varying environments. Additionally, quality control checks ensure that the devices are durable and can withstand physical and thermal stresses.

Customer Satisfaction

The quality of DC-DC converters is essential in ensuring customer satisfaction. Customers expect products to meet their specific requirements and operate as expected. Quality control checks ensure that the devices meet these requirements, and they are tested to ensure that they perform optimally. By achieving customer satisfaction, manufacturers can build a reputation for providing high-quality products leading to repeat orders and positive word of mouth.

Efficiency and Cost-Effectiveness

Quality control plays a role in improving the efficiency and cost-effectiveness of DC-DC converter manufacturing. By ensuring that the devices meet the required specifications and standards, manufacturers can reduce the number of errors, rework, wastage, and associated costs. Additionally, quality control checks ensure that the production processes are optimized and streamlined for maximum efficiency.

Conclusion

Quality control is crucial in China DC-DC converter manufacturing as it ensures that the devices meet the required specifications, performance standards, and safety regulations. Quality control helps to enhance product reliability, customer satisfaction, and cost-effectiveness of manufacturing. Manufacturers must invest in quality control techniques such as SPC and FMEA to minimize defects and optimize the production process. By doing so, they can ensure that the devices perform optimally under varying conditions and environments. With the increasing demand for DC-DC converters across various industries, manufacturers must strive to provide high-quality products through quality control, ultimately leading to business growth and customer satisfaction.

Precedente: How to solve the problem of power module selection

Prossimo: Il futuro delle fabbriche di convertitori CA-CC: tendenze e tecnologie da tenere d'occhio

informazioni rilevanti

-

2023-8-7

China Medical Power Series: Empowering Healthcare through Knowledge and Innovation

In today's fast-paced and ever-evolving world, the healthcare industry faces numerous challenges in providing effective and efficient care to patients. However, with the advent of medical power series, healthcare professionals have been empowered with the knowledge and innovation necessary to overcome these challenges and improve patient outcomes. The medical power series represents a collection of cutting-edge technologies, research, and practices that aim to revolutionize healthcare delivery. This series encompasses a wide range of disciplines, including medical imaging, precision medicine, telemedicine, artificial intelligence, robotics, and more. By harnessing the power of these innovations, healthcare providers can enhance their diagnostic capabilities, optimize treatment plans, and ultimately improve patient care. One of the key components of the medical power series is medical imaging....

Visualizza dettagli -

2023-11-30

AC/DC Power Supply Module: An Essential Component for Efficient Electrical Systems

In the rapidly evolving world of technology, the demand for efficient and reliable electrical systems is constantly increasing. Whether it's powering our homes, offices, or even the devices we use daily, electricity plays a crucial role in our lives. One of the essential components that enable efficient electrical systems is the AC/DC power supply module. The AC/DC power supply module serves as a bridge between the alternating current (AC) power supplied by the utility grid and the direct current (DC) power needed by electronic devices. It converts the high voltage AC power into low voltage DC power, ensuring a stable and regulated power supply to various electronic devices. One of the primary reasons why AC/DC power supply modules are vital...

Visualizza dettagli -

2023-5-4

Designing an AC-DC Converter Circuit

Introduction An AC-DC converter is a circuit that transforms AC (alternating current) power into DC (direct current) power. This is a necessary function in many electronic devices that require a steady and reliable source of DC power. In this article, we will discuss the design of an AC-DC converter circuit. Design considerations When designing an AC-DC converter circuit, there are several important considerations that need to be taken into account. These include the input voltage, output voltage and current, efficiency, and cost. Additionally, the type of load the converter will be powering must also be considered, as some loads may require a more stable output voltage than others. Input voltage The input voltage of the AC-DC converter circuit will depend...

Visualizza dettagli -

2023-6-4

DC Power Conversion: Understanding the Basics and Best Practices

Power conversion is an essential process in modern electronics, enabling devices to operate using different voltage and current levels. In this article, we will take a closer look at DC power conversion, its basics, and best practices. DC power conversion refers to the process of converting DC voltage levels from one level to another. This process is necessary because different electronic devices operate using different voltage levels. For example, a smartphone may operate using a voltage of 3.7 volts, while a laptop may require a voltage of 19 volts. To ensure that electronic devices can operate efficiently and safely, DC power conversion is used to convert the voltage levels to suit the specific needs of each device. The process of...

Visualizza dettagli -

2022-5-11

Quali sono i suggerimenti per la scelta di un modulo di alimentazione CC/CC?

Durante il funzionamento del sistema, l'alimentazione ha una grande influenza sulla stabilità del sistema. La scarsa qualità e stabilità del modulo di alimentazione non solo porterà a un funzionamento instabile del sistema, ma danneggerà anche seriamente i componenti. La scelta di un buon modulo di alimentazione sarà un argomento molto importante Il vantaggio di scegliere un modulo di alimentazione CC/CC ad alta stabilità è che può ridurre il tempo necessario al personale di ricerca e sviluppo per progettare in modo che il personale di ricerca e sviluppo possa concentrarsi sul prodotto stesso, ottimizzare il prodotto, accorciare i tempi di sviluppo e verifica del prodotto e portare il prodotto sul mercato. , conquistare il mercato e conquistare affari. 1. efficienza: nell'era della promozione globale...

Visualizza dettagli -

2023-8-25

SP Series made in China: The Ultimate AC/DC Converter Solution

Where technology is advancing at an unprecedented rate, the need for efficient and reliable power solutions is more vital than ever. Whether it's for industrial applications, telecommunications, or renewable energy systems, finding the right AC/DC converter is essential to ensure optimal performance and maximize energy efficiency. And that's where the SP Series comes into play - the ultimate AC/DC converter solution. The SP Series is a range of power converters designed to meet the most demanding requirements of modern-day applications. With its cutting-edge technology and innovative design, it provides a seamless and efficient power conversion solution for a wide range of industries. One of the key features of the SP Series is its versatility. It supports both AC and DC...

Visualizza dettagli